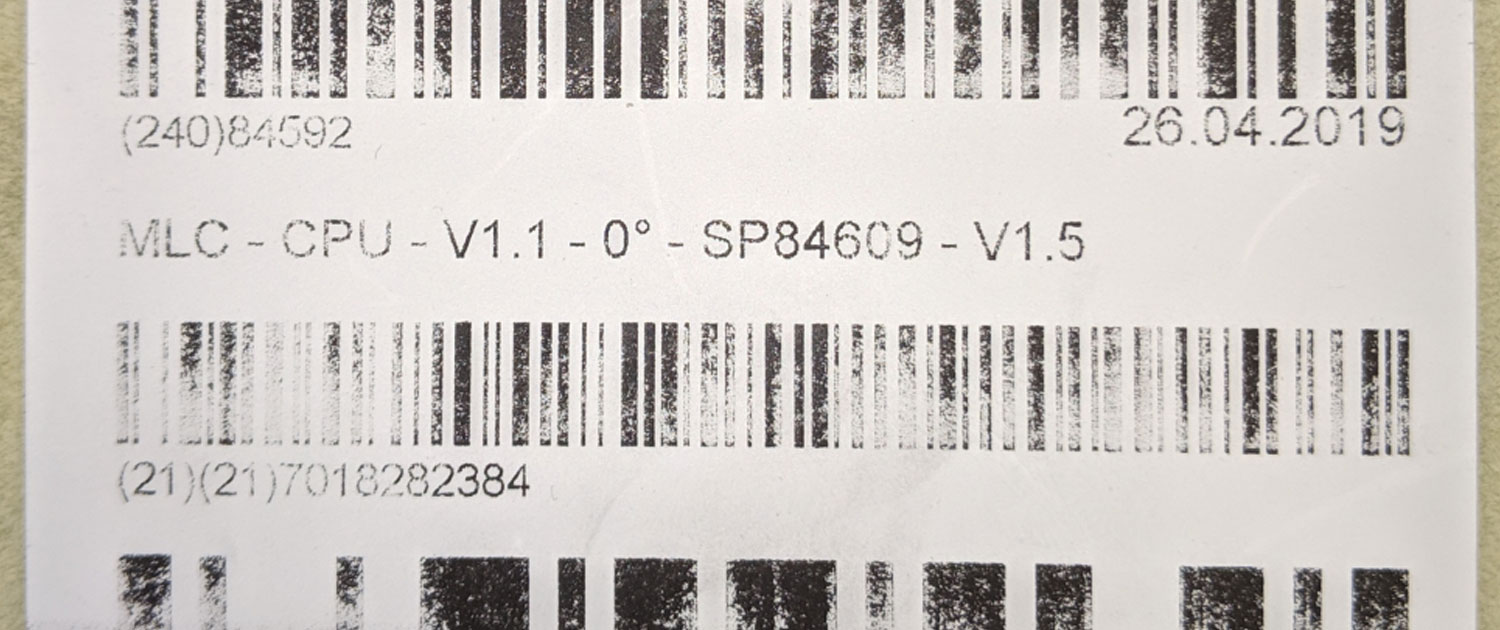

Thermal Transfer Printing Basic Troubleshooting

Barcode Direct

Bar Growth

Print speed too high – reduce speed

Old or inferior ribbon media – replace media

Use fresh (not older than 1 year) ribbon; use premium – grade consumables

Insufficient print Contrast Signal (PSC) or Light Image

Print head overheats – reduce print speed / energy

Faded image – ribbon and media incompatible

Consult supplier for compatible ribbon / media combination

Unable to Sustain Proper Wide / Narrow Ratio

Under Burn (not enough ribbon transfer) – raise energy setting; use a ribbon with a higher sensitivity

Over Burn (too much ribbon transfer) – reduce energy setting – use a ribbon with lower sensitivity

Bars too thick – reduce energy setting; improve media / ribbon quality

Streaks or Dead Spots

Wrinkled ribbon

Printhead misalignment – realign print head

Adjust print head pressure

Guide bar misalignment – realign guide bat

Reduce print energy

Make sure ribbon width is only slightly wider than label

Adjust rewind tension

Pits or Voids, Inconsistent Image Quality

Dirty print head – clean out print head

Dust on label media

Poor Edge Definition

Printing too fast – reduce speed

Ribbon and media incompatible

Leading and/or Trailing Edges of Image are Translucent (“Ghosting”)

Slew rate to print rate is too high – reduce slew rate, one level at a time

Print head temperature is too low – increase print head temperature one level at a time

Barcode Direct Difference

Here are just some of the reasons why we’ve become Australia’s most trusted barcode supplier.

Our Partners

We partner with industry-leading brands to ensure we supply only the best, most reliable products.

Get a FREE quote today

Our industry knowledge combined with in-depth product and technical know how ensure you will get the solution that best suits your needs.

OFFICE

1/47 Mustang Drive, Rutherford NSW 2320, Australia

OPEN HOURS

Monday – Friday: 9am – 5pm

Saturday – Sunday: Closed

"*" indicates required fields